| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : U TECH

Model Number : BST-120

Certification : CE SGS ISO

Place of Origin : Jiangsu, China (Mainland)

MOQ : 1 Set/Sets

Price : discussible

Payment Terms : L/C, T/T

Supply Ability : 15 Set/Sets per Month

Delivery Time : 45 work days

Packaging Details : Wooden Case for 5L-10L-15L-20L HDPE Plastic Jerry Can Tank Container Drum Extrusion Blowing Mould /Blow Molding Machine

Material : Stainless Steel

PLC : MITSUBISHI

Control System : PLC+touch Screen

Operation screen : SIMENS

Warranty : 2 Years

Mould Cavity : 1

Weight : 20T

Output : 160-200kg/h

Size : 5.8*2.9*4.3m

Water consumption : 180L/min

Blowing pressure : 0.8Mpa

Full automatic plastic 120L Jerrycan extrusion blow molding machine

Introduction

Our machine is equipped with SEIMENS PLC control system,operating manual in English, hydraulicy system operated, clamping by hydraulic system .Moreover,It is also equipped with de-flashing system, resulting in saving time and manual cost for clients, servo motor elected for energy saving. its Suitable for various materials, such as PE/PP/PVC/PS/EVOH/EVA/PET and so on. it was used to make various kinds of plastic products, such as oil jerry can, detegent bottle ,cosmetics bottle, pharmaceutical bottle, food package, plastic toys, Christmas ball, plastic lubricating oil bottle.

1. The machine adopts toggle articulated clamp system to ensure bigger clamp force and more beautiful goods. The servo valve and controller are from MOOG(USA),and both devices are able to ensure the evenness of wall thickness and the products’ elegant appearance.

2. It can be installed with programmable computer control and realize whole line automatic. The low-voltage electrical apparatus comes from Siemens(Germany), and Schneider(France).

3. Provide products with high stability for customers

4. Using famous server driver, special close loop calculated solution best energy saving. The servo drivers and energy accumulator are used to be more economical.

Feature

1. Extrusion system: Drives by a generator with frequency conversion, our extrusion system can realize the requirement of a transformable rotate speed of the screw for the blow machine process.

Screw with a big length-diameter ratio, has a good capability for processing all kinds of plastic with high plasticizing efficiency, low power expenditure.

Controlled by computer, the raw material accumulator heats by resistance-circle can be heats promptly with a stable and well-distributed temperature.

Products with content level line or double-layer, triple-layer can be produced when 2 or 3 machines work together on the team extruding system with different die-head one each machine.

2. Import linear guide rail with double station leads flexible and stable movements for the mould.

3. Hydraulic system: Optimized hydraulic oil loop design gains a stable, fast, energy saving property.

4. Electrical control system:Siemens PLC human-machine interface control system, automatic fault-alarm, credible and highly automatic work, available for 40 molding process data in the computer.

5. Capable of manual, half-automatic and full-automatic operating methods.

6. Safety system : Electrical and mechanical safety structures (stop working automatically when safety door open) guarantee operating security.

7. Blow device : Straight-insert and skew-insert blowing devices for two kinds of blowing function.

8. Leverage clamping system: Stronger clamping force with lower consumption, central clamping mould, and stable movement.

9. Linea opening system: Fast movement, accurately location.

Components list

COMPONENTS NAME | BRAND | ORIGIN |

PLC | MITSUBISHI | Japan |

Operation screen | SIMENS | Germany |

Parison control system | MOOG | Japan |

Inverter | MITSUBISHI | Japan |

Pneumatic parts | FESTO | Germany |

Hydraulic pump and valve | YUKEN | Japan |

Transducer | GEFRAN | Italy |

Contactor | SCHNEIDER | France |

Relay | SCHNEIDER | France |

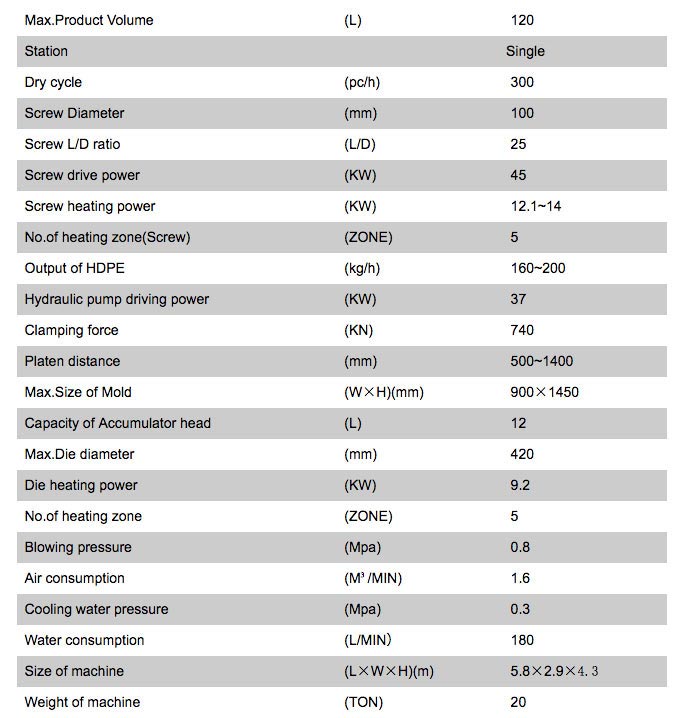

Parameter

|

|

Water Tank Fully Automatic Blow Moulding Machine 120L Jerrycan Extrusion Images |